Heavy Fabrication at Swanton Welding

Heavy Fabrication is a type of fabrication that involves very large or oversized components and materials. Not all fabrication companies can handle heavy fabrication projects. If they do handle heavy fabrication projects, they may not be able to complete smaller sub-tasks associated with the overall project.

It’s important to find a heavy fabricator who has a diverse offering of services and a highly skilled team to complete the job.

Chapters

Overview

With heavy metal fabrication, we take raw materials and bend, roll, and weld them into a finished piece down to the unique specifications you need for your project.

For heavy metal fabrication, Swanton Welding creates the majority of the project in our Heavy Fab facility located in Wauseon, Ohio. Our Heavy Fab facility has space, proper equipment, and capabilities to produce an oversized fabrication project.

Unique to Swanton Welding, we can create the smaller more intricate pieces of your project at our headquarters in Swanton, Ohio, or at our Southern facility in Griffin, GA. Having the ability to keep more of your project within Swanton Welding helps reduce any delays in shipping or turnaround time when you subcontract work to another fabricator.

Heavy Fabrication Project Types

One can find many examples of heavy fabrication in their area. At Swanton Welding, if you can dream it, we can bring your fabrication project to life. Here are some examples of past Heavy Fabrication projects.

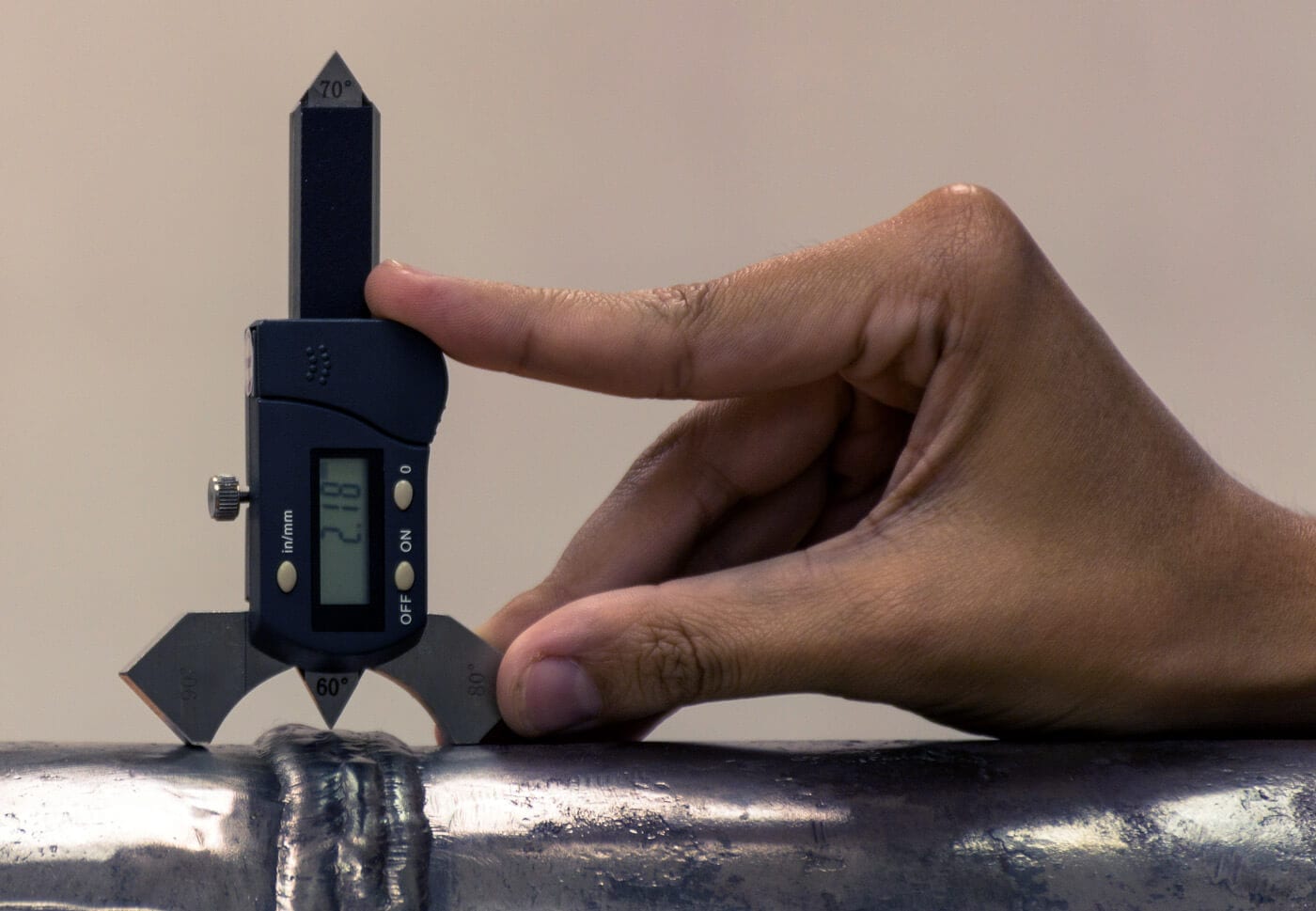

Inspection

Having a Certified Welding Inspector (CWI) inspector on staff at your fabrication company shows that the company is willing to make an investment to get the job done right. Swanton Welding has a dedicated Certified Welding Inspector (CWI) in-house that inspects every project.

Having a Certified Welding Inspector (CWI) inspector on staff at your fabrication company shows that the company is willing to make an investment to get the job done right. Swanton Welding has a dedicated Certified Welding Inspector (CWI) in-house that inspects every project.

Swanton’s in-house certified welding inspector has the ability to ensure that your fabrication project adheres to all the requirements before, during, and after your project is completed.

Our CWI inspects the requirements and welding codes of a project before any work is completed. They also review all the documents and testing records of anyone working on the project to make sure they are certified to perform the work – before the work begins. These checks and balances help ensure your fabrication project has the right people, material, and certifications all lined up before work begins.

An inspector follows the project throughout, helping make adjustments to make sure that Swanton Welding’s high-quality standards are met.

Having a CWI on staff helps us continue to maintain best practices and safety standards for our staff and your fabrication project.

Finishing Services – Industrial Painting, Powder Coating and Blasting

There is no need to subcontract our finishing services for your fabrication project. At Swanton Welding, we can handle the finishing your project needs before arriving at its destination. We can handle all industrial paint, powder coating, or blasting jobs with our high-performance equipment and provide you with the required profile for your project.

Paint & Powder Coat Booth Sizes

Paint Booths

- 75’ x 32’ x 28’

- 50’ x 14’ x 16’

- 48’ x 14’ x 14’

Powder Coat Line

- 2’ x 4’ x 6’ (up to 250lbs)

Blast Booth

- 60’ x 16’ x 14’

- Continuous Reclaim System

- 120 PSI operating pressure

- Blasts carbon steel, stainless and aluminum

- Media: G80 Steel Grit & G80 Australian Garnet

Industries Served

Swanton Welding offers a diverse range of services for many industries. With our quality certifications and our skilled workforce, we are able to complete fabrication projects that help keep America strong.

- Aerospace

- Agricultural

- Architecture

- Chemical

- Oil & gas, industrial

- Alternative energy

- Government

- Clean Air & Water

- Industrial Construction

- Many more

Integrated Manufacturing & Fabrication Teams, All Under One Name… Swanton Welding

Swanton Welding is different. Our diverse range of talents and skills set our services apart from other metal fabricators. Swanton Welding offers our customers comprehensive fabrication services at an affordable price. From robots creating widgets to skilled fabricators handcrafting oversized pieces with precision, Swanton Welding is the team your project deserves. Our footprint in the south and midwest enables us to work on almost any fabrication project.

Swanton Welding is different. Our diverse range of talents and skills set our services apart from other metal fabricators. Swanton Welding offers our customers comprehensive fabrication services at an affordable price. From robots creating widgets to skilled fabricators handcrafting oversized pieces with precision, Swanton Welding is the team your project deserves. Our footprint in the south and midwest enables us to work on almost any fabrication project.

Since 1956, Swanton Welding has been providing our customers with the highest quality services for their metal fabrication needs. Swanton Welding’s experienced team of fabricators, welders, painters, and technicians have enabled Swanton Welding to be the comprehensive fabrication team your project needs.