Inside the Process of Steel Detailing

Steel detailing is a critical and multifaceted step in the process of constructing anything made out of steel be it buildings, industrial plants, bridges, elevators, air handling units, and non-building structures. The structural engineer and/or architect conceives an idea about a project and puts this on paper in a general way. These drawings could also contain items linked to mechanical systems which pertain to the fabrication of the steel members.

Next in the steel detailing process, the steel detailer takes these design drawings and transforms them into meticulous diagrams for each steel piece. He produces drawings and plans for the making and erection of steel members such as beams, trusses, columns, braces, stairs and handrails, metal decking and joists.

Shop Drawings

In steel detailing, the detailer’s drawings covering the making of these steel pieces are called shop drawings. They identify the precise specifications for fabricating each member/piece of a structure.

The steel fabricator uses these drawings, (also called detail drawings) to produce these members. With steel detailing, comprehensive shop drawings may include for each piece:

- Size

- Material specification

- Required dimensions

- Surface preparation

- Bolting

- Welding

- Painting requirements

- Manufacturing conventions

- Special fabricating instructions.

With steel detailing, once the steel fabricator produces the steel members, the steel detailer steps in again and produces the drawings for the erection of the steel members in the field. These are called erection drawings.

Erection Drawings

It is the construction site steel erector who refers to these drawings in the steel detailing process, in order to know how and where to build with the fabricated steel pieces. Included in the erection drawings are dimensional plans to identify the steel members, in addition to all work required on the site including welding, bolting, and installing masonry anchors.

Additional Duties and Responsibilities

For the detailer in the steel detailing process:

- Observes design drawing parameters and with industry standards like those of the American Institute of Steel Construction (AISC) and the American Welding Society (AWS).

- Presents his drawings to the structural engineer and/or architect for evaluation before their release to the fabricator.

- In cases where structural drawings have inadequate information, offers links subject to the sanction of the structural engineer.

- If the detailer is uncertain about any information which prevents him from completing the drawings, they send a request for information (RFI) to the relevant parties before continuing.

- Sends his drawing to another steel detailer (labeled the “checker”) for completeness and accuracy.

- To monitor changes during the drawing creation process, identifies the revisions by assigning an associated number or letter code in the drawing revision block.

- Must resolve any comments which may have come out of the checking and approval process.

Techniques

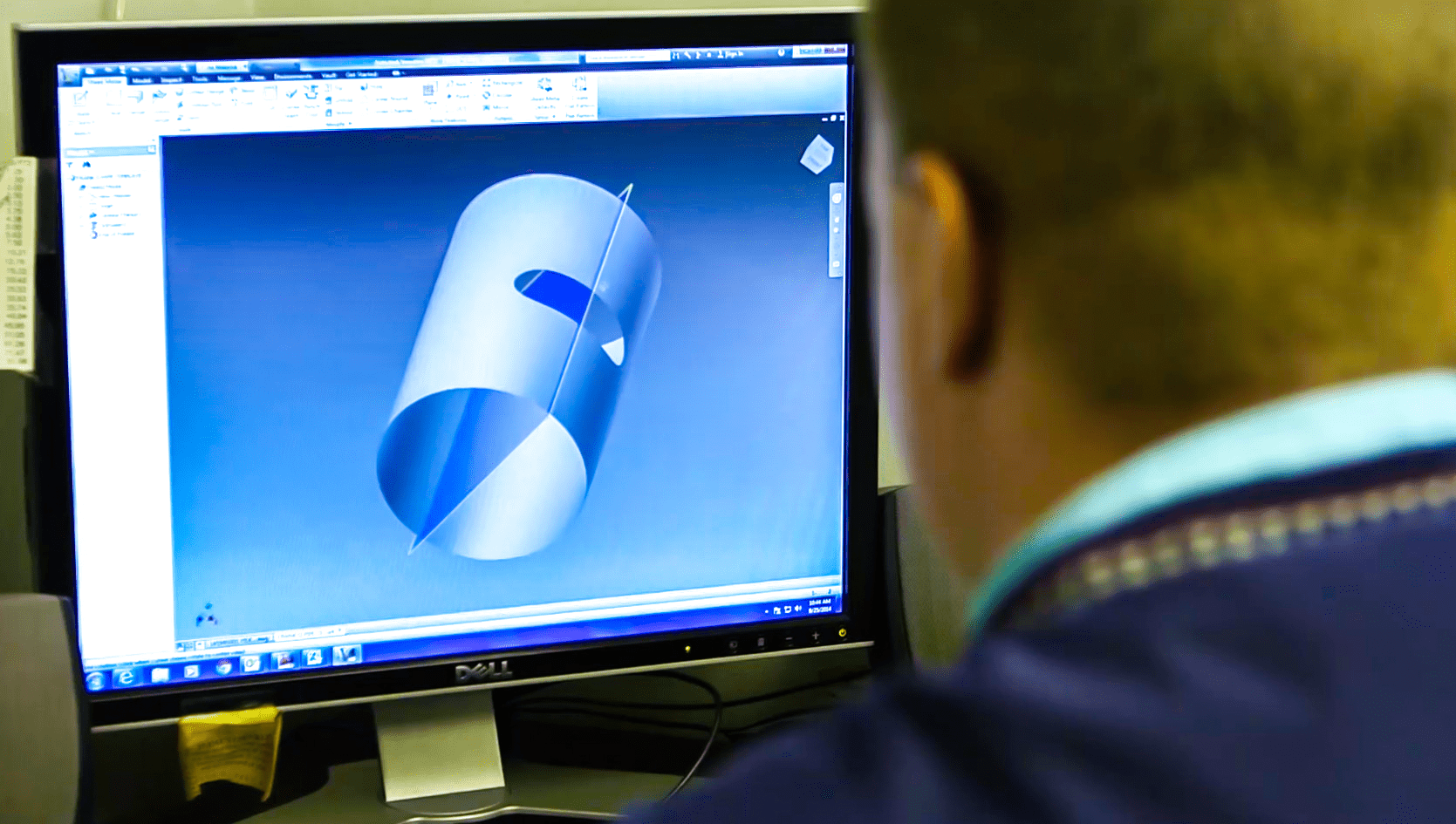

Computer-aided drafting (CAD) has replaced manual drafting for the most part in steel detailing. The detailer using these systems generate his drawings on the computer, employing software designed for this purpose, and then prints them. Accordingly, in the skills needed for steel detailing, the detailer needs proficiencies in the use of computers and comprehension of the particular CAD software he will utilize.

Steel detailers add another category for those working with 3-D modeling applications. The process for the construction of these drawings is very different from two-dimensional drafting. In this case, the project is built in 3-D before production of shop drawings from the model.

Drawings can be downloaded into a Computer Numerically Controlled (CNC) file and automatically begin drilling and cutting each part. In the process, each piece is fixed with a part number and plate location. 3-D modeling systems include X-Steel, Intergraph, Modeldraft/Frameworks Plus, AutoCAD, and Microstation.

The steel detailer has an extremely critical role in the steel detailing process. He links to the structural engineer, the architect, general contractors, the steel fabricator, the steel erector, the checker, relevant people in the CAD and CNC computer processes, and more. In the flow of steel detailing, the detailer’s shop and erection drawings are crucial to the entire process.