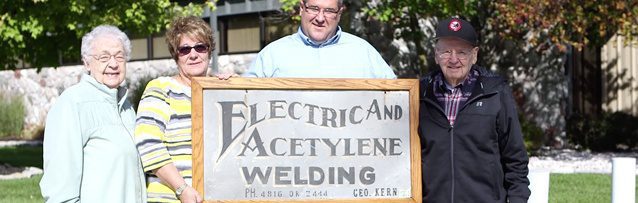

Swanton’s Early Welding History

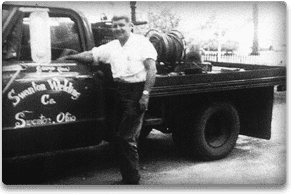

George Kern learned the craft of welding as an airplane mechanic while stationed in the Aleutian Islands with the Navy during World War II. Once back home from the service, George recognized a need the local farming community had for welding services and launched Swanton Welding & Machining in 1956. As a small welding shop, the company’s focus was on equipment repair for farmers and small factory projects. After Kern put in three years of nearly around the clock work six days a week, it became a full time operation by 1959 in an era when welders faced plenty of competition.

In 1973, growth continued and George brought on Norm Zeiter (his son-in-law) as his first full time employee. Two additional employees were added shortly after and by 1980, they had grown to a total of six employees.

They expanded their facility to 1,500 square feet only to get caught in a recession, yet the business still grew from 1981 to 1983.

After three decades, George Kern decided to retire in 1985. It seemed natural that Norm Zeiter would purchase the business and take over the reigns. One Norm’s first moves was adding a new building, which became the main facility in Swanton, covering 8,000 square feet. It was quite a gamble, but the strategy of partnering with a local factory and focusing closely on customer needs led to long term loyal relationships and business growth.

After three decades, George Kern decided to retire in 1985. It seemed natural that Norm Zeiter would purchase the business and take over the reigns. One Norm’s first moves was adding a new building, which became the main facility in Swanton, covering 8,000 square feet. It was quite a gamble, but the strategy of partnering with a local factory and focusing closely on customer needs led to long term loyal relationships and business growth.

Norm expanded the company from a small welding shop to one of the Ohio’s largest metal fabricators.

Business Boom of the 90s

Swanton Welding’s expansion paid off during the 90’s economic boom, which was driven partly by manufacturing. After years of gradual transition from an agriculture repair shop to a facility serving local factories, the company made custom metal fabrication one of its main services. The main Swanton facility doubled its size in 1993 to 17,000 square feet. From 1985 to 1999 the company enjoyed a great deal of growth due to a strong local economy, an expert workforce and an ability to handle increased workflow. From the late 90s through the early 2000s the facility expanded further to 275,000 square feet, using the same state of the art equipment they had staked their reputation on. By that point the Swanton operation had grown to 60 employees. Expansion continued in 1997 with the launching of the company’s Griffin, Georgia facility in a small building that grew to 65,000 square feet in manufacturing space.

Swanton Welding’s expansion paid off during the 90’s economic boom, which was driven partly by manufacturing. After years of gradual transition from an agriculture repair shop to a facility serving local factories, the company made custom metal fabrication one of its main services. The main Swanton facility doubled its size in 1993 to 17,000 square feet. From 1985 to 1999 the company enjoyed a great deal of growth due to a strong local economy, an expert workforce and an ability to handle increased workflow. From the late 90s through the early 2000s the facility expanded further to 275,000 square feet, using the same state of the art equipment they had staked their reputation on. By that point the Swanton operation had grown to 60 employees. Expansion continued in 1997 with the launching of the company’s Griffin, Georgia facility in a small building that grew to 65,000 square feet in manufacturing space.

The new facility, which employed 25 people, specialized in the following services:

- robotic welding

- laser cutting

- precision forming

- powder coating

- customer fabrication

- production fabrications

Heavy Fabrication Facility

After years of establishing itself as a resilient manufacturer and assisting Caterpillar with assembly line production, SWC launched an 85,000 square foot Heavy Fabrication Facility in Wauseon, Ohio with 25 employees in 2009. The purpose of this new factory was to handle larger projects such as railroad fabrications, heavy conveyor systems, bulk material handling and other industrial projects from utility to mining work. With three modern facilities, Swanton Welding is able to specialize in just about any type of metal or steel project imaginable. Here are some of the company’s current capabilities:

After years of establishing itself as a resilient manufacturer and assisting Caterpillar with assembly line production, SWC launched an 85,000 square foot Heavy Fabrication Facility in Wauseon, Ohio with 25 employees in 2009. The purpose of this new factory was to handle larger projects such as railroad fabrications, heavy conveyor systems, bulk material handling and other industrial projects from utility to mining work. With three modern facilities, Swanton Welding is able to specialize in just about any type of metal or steel project imaginable. Here are some of the company’s current capabilities:

- mixing tank fabrication

- acid furnace fabrication

- steel thrustframe fabrication

- industrial conveyor fabrication

- steel stack fabrication

The Story Continues

One of the reasons contractors turn to Swanton Welding is because structural steel construction has several advantages over other building methods. Structural steel can be useful for building both residential and commercial properties due to its low maintenance and sturdy framing that can withstand disasters. Swanton Welding is also favored by big contractors because it offers finishes in addition to custom welding and fabrication. Other services include painting, blasting, steel processing, rolling and forming and a variety of machining processes.

Today Swanson Welding lives on in the new century with the goal of becoming one of the most diversified steel fabricating companies in the United States. The company continues to set high standards for quality, custom metal fabrication and on-time delivery. Although Norm passed away in 2014, the company preserves his passion for meeting customer needs with the help of quality equipment and dedicated employees who have stayed with the company for over 25 years.

Key to SWC’s Longevity

So how has SWC managed to stay in business for 60 years, outlasting several recessions and a long list of competitors that have come and gone? The main key is that the company only hires certified welding experts who strive to keep making its customized services better. By focusing on the needs and desires of its customers, the company has built strong loyal relationships.

Another secret to SWC’s longevity is that it treats customers as partners. Instead of offering one size fits all services, the company bases projects on what the customer needs done, whether it involves welding for energy utilities, military, agriculture or other industries. The company builds towers, conveyor systems, truck beds and farming equipment, as no project is too big.

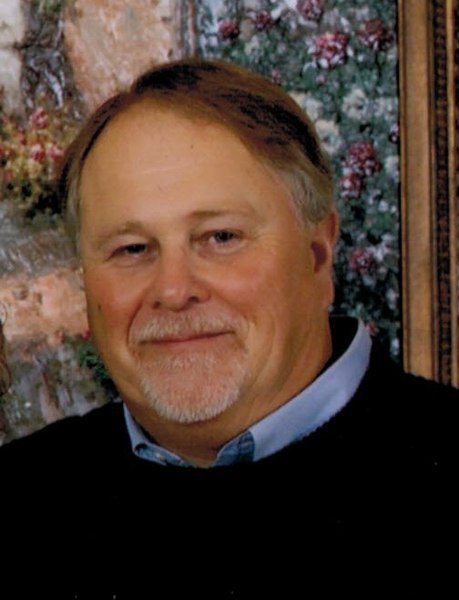

Norm’s Memory

Although Norm Zeiter passed away on May 1, 2014, the company preserves his passion for meeting customer needs with the help of quality equipment and dedicated employees who have stayed with the company for over 25 years. Norm established the current culture at Swanton Welding, which grew from a two-man weld shop to what it is today. His memory lives on through the principles he taught that reflect his belief in servicing the customer, as well as investing in quality equipment and talented people.

Although Norm Zeiter passed away on May 1, 2014, the company preserves his passion for meeting customer needs with the help of quality equipment and dedicated employees who have stayed with the company for over 25 years. Norm established the current culture at Swanton Welding, which grew from a two-man weld shop to what it is today. His memory lives on through the principles he taught that reflect his belief in servicing the customer, as well as investing in quality equipment and talented people.

Continuing his father’s legacy, Norm E. Zeiter proudly serves as president today. The company is blessed with an experienced team that understands and lives the values that are so important to making Swanton Welding and Machining the company it is today.

Swanton Welding has not only served loyal customers for decades with quality custom solutions, it has maintained the highest of standards in the process. It’s a company built from the ground up that values teamwork and helping other businesses become as strong as steel.

We appreciate you taking the time to learn about our proud company history.

Sincerely,

Norm E. Zeiter

President