Why Flying Optics Give a Competitive Edge

New technologies and equipment are continually improving the metal fabricating industry. For businesses to thrive in this competitive industry they must embrace the latest trends in the field. One of the most recent cutting techniques in the industry involves the usage of flying optics laser systems. A metal fabrication business that embraces this type of cutting system can gain a competitive edge over its competitors.

There are three types of laser cutting configurations used in the metal fabrication industry. They are defined by the way their laser beam processes or cuts a material. These cutting machines include hybrid laser systems, the moving material laser cutter, and flying optics laser systems. Most laser cutting configurations process/cut items by the X- and Y-axes. However, some might feature a manipulateable cutting head, which can be used to cut an item on the Z axis.

The moving material laser cutting machine has a stationary cutting head. Therefore, the object being cut is moved underneath the cutting head. This type of cutting configuration is best used on flat materials. On the other hand, the hybrids feature a laser head which moves on one axis (the Y-axis) and a stationary table which handles the material being cut; this table moves on the opposite axis from the laser head (usually the X-axis).

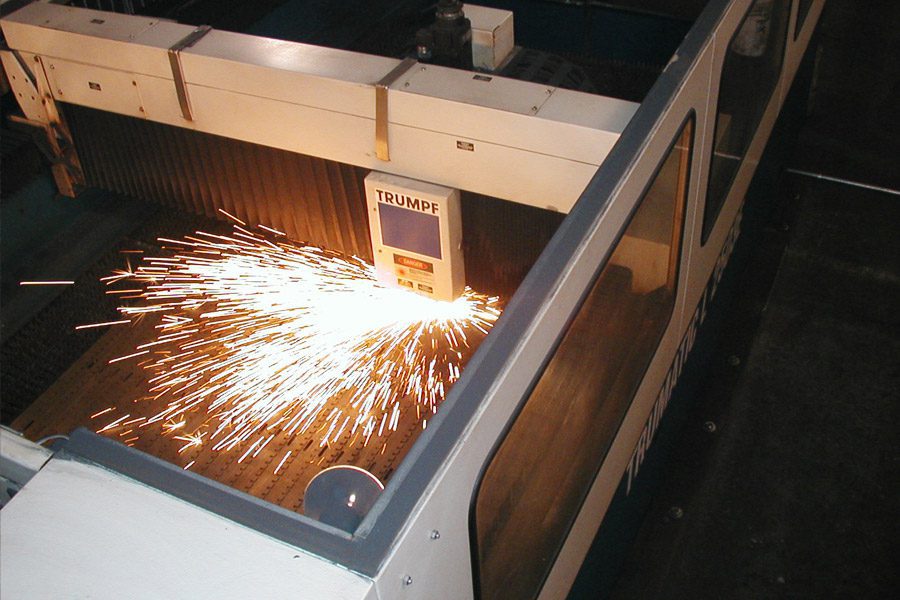

The flying optics laser cutters, on the other hand, work by moving their laser beam over stationary material. The handling table on these systems is designed to hold the material during processing, hence no need for clamping. The laser beam in these cutters processes a material on both the X- and Y-axis. Flying optics laser machines are considered to be the most superior among the three types of cutting machines. Here is why:

Versatile

This laser cutting machine is not affected by the weight or width of the material being cut. This is because the powerful laser beam is moving on both the X- and Y-axis continuously. This means that businesses who use flying optics laser cutters can cut a wider array of materials allowing them to accept a more diverse range of clients.

Faster

When compared to the moving material laser cutting machines and the hybrid systems, the optics laser machines work at a higher speed. This is because both the X- and Y-axis are being cut simultaneously, hence faster output. Also, the material being cut remains stationary which makes positioning fast. In short, companies that use flying optics laser cutters can take on more jobs with the knowledge that they will be able to complete them in an efficient fashion.

Cleaner

While the first laser of the flying optics laser cutter cuts a hole on the surface of the material, the second laser stops the slag from sticking into the cut hole, hence giving you a cleaner “piece of slice”, which is more attractive to buyers and homeowners.

High Quality

The quality of the cut made by the laser system is better than that produced by other types of systems. This results in a more reliable end product and ensures the effectiveness of the system every time it is used.

Flying optics machines certainly offer you advantages that other laser machines cannot. This type of laser cutting configuration is fast, it is accurate, and it is precise. The features of this machine can improve efficiency and guarantee quality, and as such it is hugely beneficial to any businesses that purchases one, both to the business itself and to its customers.