New Specialty Rolling Capabilities

At Swanton Welding, we take pride in meeting your exact specifications when it comes to custom metal fabrication. We pair our exceedingly experienced fabricators with top-of-the-line equipment. This is just one of the many ways we proudly put our best foot forward no matter what job we’re doing.

Our metal rolling and forming services recently improved dramatically with the acquisition of a Davi MC4P11, the industry-standard when it comes to metal rolling and forming. Italian-made from the same region that produces Lamborghinis, Maseratis, Ducatis, and Ferrari. Quite frankly, Davi-produced equipment performs up to those same “Made in Italy” standards.

Inside the MC4P11

Much like Swanton Welding, Davi believes that the final product is a sum of its parts. Davi ensures every MC4P11 they produce meets their rigorous standards by only sourcing parts from suppliers that are ISO 9001-certified.

All this attention to detail allows the Davi MC4P11 to maximize unit uptime and performance. It also gives the unit the ability to bend any type of metal to exact specifications. The MC4P11 utilizes “roll-by-wire” and friction-free “swing guides” technology. There’s no better rolling and forming piece of equipment in the world.

What is Roll-by-Wire?

Much like the terms “fly-by-wire” in the aerospace or automotive industries, “roll-by-wire” is the ability of the MC4P11 to function completely in the digital space, instead of the relays and contacts that older machines use. All-digital technology is not only faster, but it’s more reliable.

Going all-digital reduces the number of components, allowing the unit to be designed much more compactly. User-friendliness is also increased. Rolls are more accurate overall, and performance speed is also increased.

Performance

With that kind of pedigree, it’s not hard to imagine the capabilities of the MC4P11. There’s no bending or forming process it can’t handle. High accuracy and repeatability are its hallmarks, whether working with mild steel, stainless steel, or aluminum materials.

Technical Data

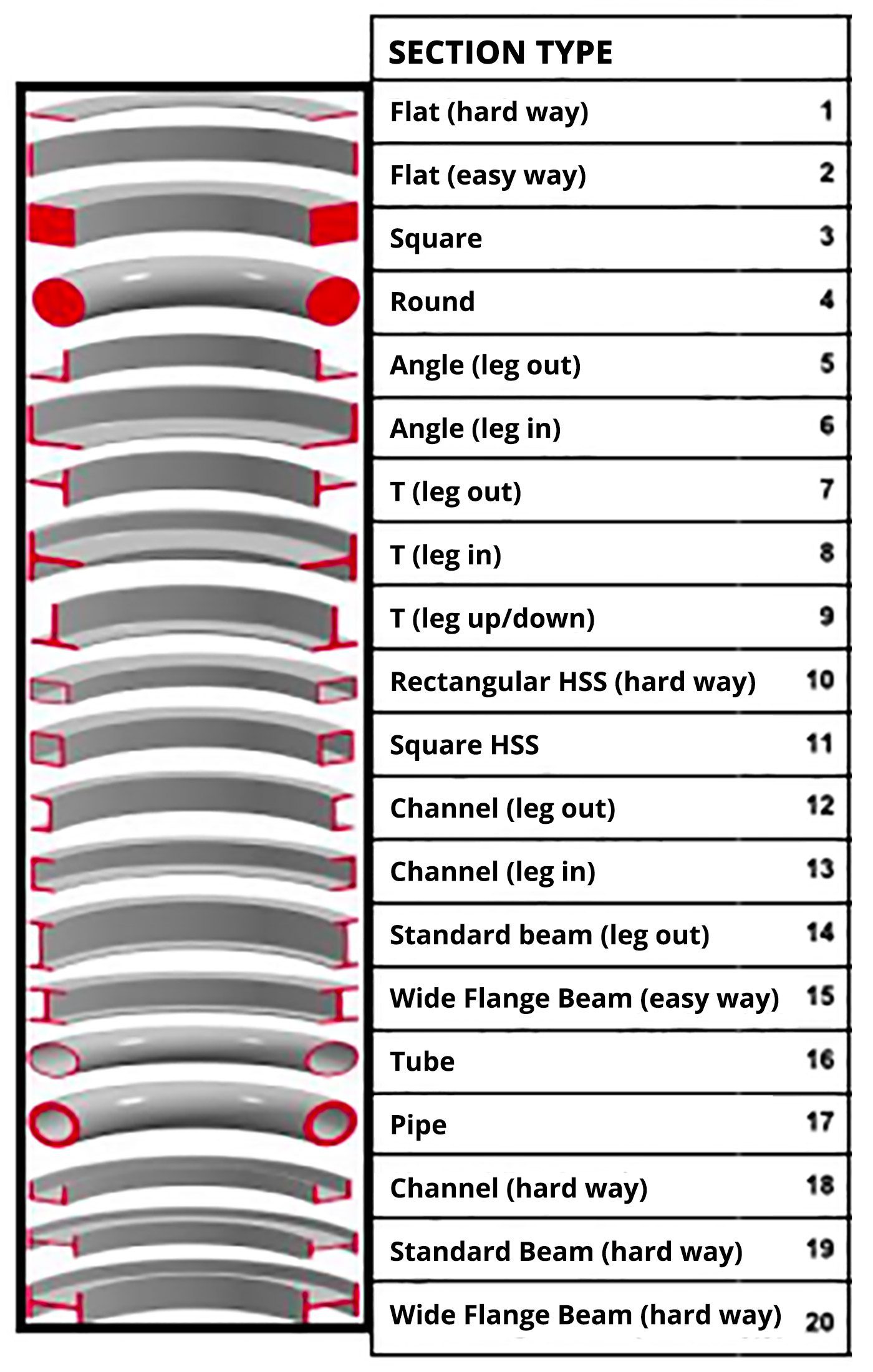

The MC4P11 is capable of forming and rolling many different metal material shapes:

Four independent motors drive the four powered rollers, with each delivering at a rate of 23 feet per minute. The planetary guides are friction-free, mill-scale proof, and hydraulic. The self-aligning spherical roller bearings ensure the chromium-plated hydraulic cylinders perform every time. All vertical, horizontal, and angular bends are performed automatically.

The Davi MC4P11 is the only angle roll unit that powers all four rollers as a standard feature. Having all four rollers powered allows us to ensure that there are no errors due to slippage during pre-bending.

The Bottom Line

Bringing the MC4P11 onboard at Swanton delivers the best of both worlds to you, our customer. Our stated goal is to become the most diversified specialty steel fabricator in the United States, and with our new Italian import, we have moved ever closer to that.

However, simply rolling out a new top-of-the-line machine doesn’t do much without skilled and experienced fabricators to operate it. At Swanton, we’ve been working in the metal fabrication business since 1956, and we bring all of that experience and wisdom to every build. Our dedication to delivering your parts on-time and exceeding your expectations is what it’s all about.

The next time you bid out for custom metal fabrication, think beyond simply choosing the lowest bid, and consider what goes into it. Is pretty good going to be good enough for your project? Or do you expect performance that matches your own high standards?

By combining the best metal fabricating professionals in the midwest with the world’s best technology, there’s no one that can match the overall quality and customer service that Swanton Welding can offer. Contact our team to learn more about the impact Swanton Welding can make in your next custom metal project.