How Is Structural Steel Made in the United States?

For more than 5,000 years, the human race has profited immensely from the use of metals for one reason or another. This benefit was increased enormously with the development of steelmaking, especially as it refers to the creation of structural steel in the 19th century by the Henry Bessemer’s reconditioning process. The technology of modern steelmaking has continued to progress into the 21st century. Here is a quick history of how it all came to be and where it stands now:

History

- Pre-Bessemer steel – Before Henry Bessemer, an English inventor, developed the first technique of modern steelmaking, all steel objects were either forged or cast in crucibles. In the former process, a steel ingot is subjected to a number of presses that stamp or bend it into shape. In the latter, a molten steel sludge is deposited into a pre-made mold and allowed to cool. The mold is then removed and the metal piece further refined mechanically. Both processes have their benefits and drawbacks but forging is essentially useless for creating large pieces of structural steel. It does work well for creating smaller steel pieces such as swords and cutlery.

- The Bessemer process – Probably without realizing it, Henry Bessemer created one of the most pervasive modern methods of manufacturing steel ever devised. In the process he discovered, small quantities of air – and thereby oxygen – are blown across the molten pig iron. The resulting oxidation of the material removes much of the impurities in the molten metal. These impurities either escape as gasses or form a slag on the top of the steel and are subsequently removed by a mechanical process. The final product is known as “mild” steel.

- What is the state of the technology now? – The vast majority of modern structural steel is of the mild – or low-carbon – variety. It has numerous significant benefits to its credit. Its exhibits an excellent strength to weight ratio, and easily joins to other building metals. It can also form into any number of shapes using industrial strength machines such as plate presses, beam liners, and angle detailers. In addition, it is easily and affordably produced using a method quite similar to the original Bessemer process.

The Manufacture of Structural Steel

- How modern structural steel is manufactured – Basic oxygen steelmaking (BOS) – also known as the oxygen converter process –is the primary method of steelmaking in the United States today. In essence, the process takes carbon-rich molten pig iron, heats it in an open hearth furnace, blows oxygenated air across the substrate and thus turns it into high-grade steel. In addition, a base – such as a flux of burnt lime or dolomite –– is also introduced to lower the level of impurities in the final product – hence the term “basic.” the most modern factories us electric arc furnaces (EAFs) to heat the pig iron but they can become cost-prohibitive when the price of electricity is high.

- Carbon and alloy steels – Technically, all steel has some carbon in it but alloyed steel has additional materials such as manganese, nickel, chromium, molybdenum, vanadium, silicon and boron also included in its composition. The resultant substrate may then be heat treated to increase its beneficial properties – some of which are strength, hardness, durability, wear & corrosion resistance, external hardenability, and hot hardness. In a nutshell, the latest alloys can be customized with various materials to exact specifications whenever a specific structural steel is required.

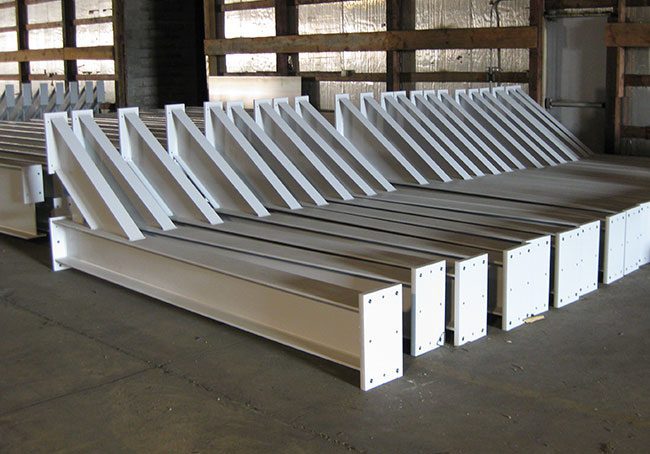

- Why use structural steel? – The latest process of structural steel manufactured today creates a versatile alloy that provides a number of benefits to the 21st-century construction world. Rolled steel can be easily formed into any number of shapes including beams and columns as well as ones with more complicated shapes such as W, S, C, angles, tube sections, and pipes. The strength, durability, and cost-effectiveness of structural steel makes it the only practical skeletal building material choice for any large-scale building project anywhere in this country.

There is an incredible wealth of technical information available on the various types of structural steel and their various benefits. For more detailed information on them or on the manufacture of basic structural steel and how it can meet the needs of your business in the United States, please contact us at Swanton Welding Company Inc. You can visit us online at SwantonWeld.com or reach us directly at 419.826.4816.